· sand blasters · 12 min read

Best Sandblaster Sand: A Comprehensive Guide to Selecting the Right Grit for Your Project

Discover the best sandblaster sand for your project! This guide provides detailed insights on different grits, helping you achieve exceptional results in metalworking, restoration, and more.

Sandblasting is a versatile technique used in various industries for cleaning, shaping, and finishing surfaces. Choosing the right sandblaster sand is crucial for achieving optimal results. This comprehensive guide will help you understand the different grits of sandblaster sand and how to select the ideal option for your project.

Overview

PROS

- Unleash unparalleled abrasive force with #80 grit aluminum oxide, delivering superior surface preparation.

- Maximize longevity with long-lasting media, ensuring consistent performance and cost-effectiveness.

- Experience effortless compatibility with diverse applications, including metalwork, sandblasters, and blasting cabinets.

CONS

- May generate dust during use, requiring appropriate protective measures.

- Abrasive nature necessitates cautious handling to avoid potential skin irritation.

Prepare yourself for an unparalleled sandblasting experience with our exceptional #80 grit aluminum oxide blast media. This premium material unleashes a formidable abrasive force, effortlessly conquering stubborn dirt, rust, and other surface imperfections. Its extended lifespan ensures unwavering performance, maximizing your value and minimizing downtime.

Our versatile sandblasting media seamlessly adapts to an array of applications. Whether you're tackling metal surfaces, operating sandblasters, or utilizing blasting cabinets, this versatile media delivers consistent, professional-grade results. Its optimized particle size ensures efficient removal of contaminants, leaving surfaces pristine and ready for their next phase.

PROS

- Precision Blasting: Achieve intricate details and a smooth surface finish with fine #120 aluminum oxide sand.

- Multipurpose Versatility: Compatible with various blasting cabinets and guns, enabling effortless sandblasting applications.

- Bulk Supply: Ample 8-pound packaging ensures uninterrupted blasting projects without frequent refills.

- Precise Abrasion Control: Calibrated #120 grit size delivers controlled abrasion, preventing damage to sensitive surfaces.

- Eco-Friendly Solution: Aluminum oxide composition ensures environmental sustainability.

CONS

- May Require Respirator: Fine particles necessitate appropriate respiratory protection during use.

- Specific Equipment Required: Requires specialized blasting equipment for optimal performance.

- Limited Versatility: Primarily suited for fine sandblasting applications, may not be ideal for heavy-duty tasks.

Experience the unparalleled precision and versatility of our #120 Aluminum Oxide Sandblaster Sand. Crafted from premium aluminum oxide, this fine-grit media delivers a controlled and intricate blasting performance, making it an ideal choice for achieving flawless finishes. Ideal for use in blasting cabinets and guns, its compatibility enhances your blasting capabilities.

With its generous 8-pound supply, you can embark on extended sandblasting projects without the hassle of frequent refills. The calibrated #120 grit size ensures optimal abrasion, preventing damage to delicate surfaces while effectively removing impurities and imperfections. Our aluminum oxide composition guarantees environmental sustainability, making it a responsible choice. However, it's essential to utilize a respirator for protection against fine particles during use.

PROS

- Exceptional abrasive force for efficient metal surface preparation

- Long-lasting media ensures cost savings and reduced downtime

- Medium #100 grit strikes the perfect balance between speed and finishing quality

CONS

- May generate dust during blasting process, requiring proper ventilation

- Not suitable for delicate surfaces, as it can cause abrasions

Transform your sandblasting projects with this premium 10 LBS #100 Grit Medium Aluminum Oxide Blast Media. Its exceptional abrasive force makes it an ideal choice for preparing metal surfaces, effectively removing rust, paint, and other contaminants. The long-lasting nature of this media ensures cost savings and minimizes downtime.

The medium #100 grit size offers a versatile solution, balancing speed and finishing quality. It is particularly effective in applications where precision and efficiency are paramount. The durability of this blast media guarantees optimal performance over multiple uses, reducing the need for frequent replacements. Whether you're a professional sandblaster or a DIY enthusiast, this premium Aluminum Oxide Blast Media will elevate your projects to the next level.

PROS

- Exceptional Medium Grit (70-80) for a wide range of blasting applications, ensuring optimal performance and efficiency.

- Consistent particle size provides a uniform surface finish, minimizing imperfections and enhancing aesthetic appeal.

CONS

- May require specialized equipment for handling and disposal.

- Can generate dust during blasting, requiring proper ventilation and protective gear.

For those seeking an exceptional sandblasting experience, our #8 Medium Glass Beads stand out as the ultimate abrasive. With a meticulously calibrated 70-80 grit level, these beads deliver unparalleled precision and versatility, catering to a broad spectrum of blasting applications. Their consistent particle size ensures a uniform surface finish, minimizing imperfections and elevating the aesthetic appeal of your project.

Furthermore, these industrial-grade glass beads are renowned for their durability, withstanding the rigors of even the most demanding blasting tasks. Whether you're tackling intricate detailing or large-scale surface preparation, our #8 Medium Glass Beads empower you with the confidence to achieve exceptional results. Invest in the ultimate sandblasting solution today and unlock a world of precision and efficiency for your next project.

PROS

- Premium-grade glass beads ensure precise and efficient blasting operations.

- Versatile 100-170 grit range accommodates a variety of blasting applications.

CONS

- May generate minimal dust during the blasting process.

- Requires appropriate safety gear for usage.

Harness the power of precision sandblasting with our exceptional Sandblasting Media Glass Beads. These premium beads are meticulously crafted to deliver exceptional results, ensuring a smooth and efficient blasting experience. Their versatility extends across a wide range of surfaces, making them an ideal choice for diverse blasting needs.

The carefully calibrated 100-170 grit range empowers you to tackle various tasks, from delicate restoration projects to heavy-duty surface preparation. Whether you're working on automotive parts, glass, or stone, these glass beads provide the precision and efficiency you demand. However, it's crucial to note that the blasting process may generate minimal dust, so appropriate safety measures are essential for a safe and comfortable work environment.

PROS

- Exceptional abrasion resistance ensures effective material removal.

- Versatile application as a sandblaster abrasive, blasting gun medium, and sand blast cabinet filler.

CONS

- Specific gravity and shape may require adjustments to blasting equipment settings.

- Fine dust generation during use necessitates proper protective measures.

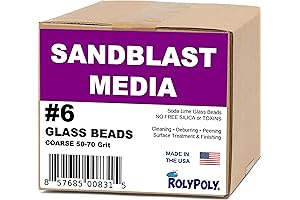

Experience the transformative power of Sandblasting Media Glass Beads #6! These coarse 50-70 grit beads deliver exceptional abrasion resistance, making them an ideal choice for demanding sandblasting projects. Their versatile nature allows for seamless integration with sandblasters, blasting guns, and sand blast cabinets.

Harnessing these glass beads empowers you to remove unwanted materials efficiently, leaving behind a pristine surface. Whether you're tackling rust, paint, or other stubborn residues, these beads ensure a remarkable finish. Their durability ensures longevity, allowing you to complete multiple projects without frequent replacements. Invest in Sandblasting Media Glass Beads #6 today and elevate your sandblasting endeavors to new heights!

PROS

- Coarse premium grade aluminum oxide for exceptional abrasive force

- Long-lasting formula ensures extended use and maximum value

- Versatile application for metal, glass, stone, and wood surfaces

- Ideal for sandblasters, blasting cabinets, and blasting guns

- 12-pound bulk packaging offers ample supply for various projects

CONS

- May require additional safety precautions due to its abrasive nature

- May generate dust or particles during use, proper ventilation is recommended

Get ready to unleash the power of precision sandblasting with #30 Aluminum Oxide, the ultimate sand blasting media designed to tackle any surface with ease. This premium grade aluminum oxide boasts exceptional abrasive force, ensuring a smooth and efficient blasting experience. Its coarse texture makes it ideal for heavy-duty applications, effortlessly removing rust, paint, or other stubborn coatings.

Unlike ordinary sandblasting media, #30 Aluminum Oxide is formulated for extended longevity, saving you time and money in the long run. Whether you're a professional sandblaster or a DIY enthusiast, this 12-pound bulk packaging provides ample supply for all your projects. Its versatility extends across a wide range of surfaces, including metal, glass, stone, and wood, making it an indispensable tool for any workshop or garage.

PROS

- Medium-grit aluminum oxide provides optimal balance between cutting power and surface finish

- Versatile for use in various blasting applications, including glass etching, rust removal, and graffiti cleaning

CONS

- May not be suitable for use on delicate surfaces

- Requires proper personal protective equipment when handling

Indulge in the world of sandblasting with our top-notch #80 Aluminum Oxide Sand! Crafted from premium materials, this medium-grit sand strikes the perfect balance between cutting power and surface finish. Its versatility shines in diverse applications, from glass etching and rust removal to graffiti cleaning. Whether you're a seasoned pro or a DIY enthusiast, this sandblaster sand will elevate your projects to new heights.

With its wide compatibility with blasting cabinets and guns, this aluminum oxide sand empowers you to tackle any blasting task with ease. Its durable nature ensures longevity, making it an investment that will keep your sandblasting endeavors running smoothly. Embrace the power of this exceptional sand and witness the transformation it brings to your surfaces!

PROS

- Exceptional versatility for various sandblasting applications, including rust removal and surface preparation.

- Medium-grade abrasive ideal for a wide range of surfaces, from delicate materials to tough metals.

CONS

- May require multiple applications for heavily rusted or thickly coated surfaces.

- Fine particles may create dust during blasting, necessitating proper ventilation.

Experience unparalleled precision and efficiency in your sandblasting endeavors with our premium #120 Black Aluminum Oxide Sand. This medium-grade abrasive strikes the perfect balance between abrasiveness and gentleness, making it suitable for a diverse array of surfaces. Whether you're removing rust, preparing surfaces for painting, or engaging in intricate detailing, our sand delivers exceptional results.

Crafted from the finest aluminum oxide, this abrasive delivers consistent and controlled performance. Its sharp, angular particles effectively remove rust, dirt, and paint without damaging the underlying material. The uniform particle size ensures minimal clogging in your sandblasting equipment, maximizing efficiency and minimizing downtime. Moreover, the sand's dark color provides excellent visibility during blasting, allowing for precise control over the process.

PROS

- 19-pound bag of premium aluminum oxide media, offering exceptional durability and longevity.

- Fine grade #120 abrasive effectively removes rust, paint, and other contaminants without damaging delicate surfaces.

CONS

- May require additional screening to remove larger particles for optimal performance.

- Fine abrasive particles can create significant dust, necessitating proper ventilation.

Experience the pinnacle of sandblasting with our exceptional #120 Aluminum Oxide abrasive media. Its rugged resilience and fine #120 grade ensure efficient removal of rust, paint, and impurities from various surfaces. Whether you're rejuvenating treasured heirlooms or tackling industrial-scale projects, this media delivers impeccable results.

Each 19-pound bag provides ample supply for multiple projects, while minimizing downtime and maximizing cost-effectiveness. Its versatility extends to both blasting cabinets and guns, offering unmatched flexibility. However, for optimal performance, consider screening the media to eliminate larger particles. Additionally, dust generation is inherent to the fine abrasive nature of this media, necessitating adequate ventilation to safeguard your respiratory health. Embrace the #120 Aluminum Oxide abrasive media as your trusted ally for revitalizing and restoring surfaces with precision and ease.

In this guide, we've explored the types of sandblaster sand available in the market, including aluminum oxide, glass beads, and black aluminum oxide. We've also provided tips on choosing the right grit based on the material you're working on and the desired finish. Whether you're a professional or a DIY enthusiast, this guide will empower you to make informed decisions and achieve exceptional results with your sandblasting projects.

Frequently Asked Questions

What is the best grit for sandblasting metal?

For metal surfaces, a coarser grit like #30 or #80 aluminum oxide is recommended for removing rust, paint, and other coatings.

Can I use sandblaster sand for glass?

Yes, but use a finer grit such as #120 or #220 to avoid damaging the glass surface.

What is the difference between aluminum oxide and glass beads for sandblasting?

Aluminum oxide is more abrasive and suitable for heavy-duty tasks, while glass beads are gentler and ideal for delicate surfaces.

How often should I replace the sand in my sandblaster?

Replace the sand when it becomes contaminated or loses its abrasive properties, typically after several hours of use.

What safety precautions should I take when using a sandblaster?

Always wear protective gear, including a respirator, gloves, and eye protection, and operate the sandblaster in a well-ventilated area.